Why CNC Plasma Cutters Are the Future of Metal Fabrication

Metal fabrication is a process that involves cutting, bending, and assembling metal components to create a finished product. It is used in a variety of industries, from automotive to aerospace, and is an essential part of the manufacturing process. In recent years, CNC plasma cutters have become increasingly popular for metal fabrication due to their accuracy, speed, and cost-effectiveness. In this article, we will discuss why CNC plasma cutters are the future of metal fabrication.

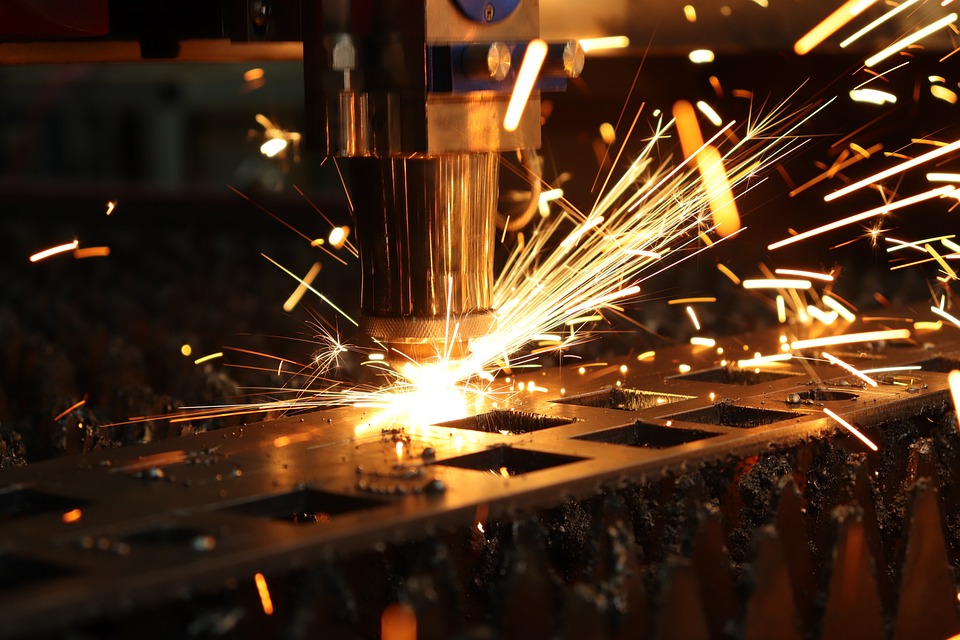

What is a CNC Plasma Cutter?

A CNC plasma cutter is a computer-controlled machine that uses a high-velocity stream of ionized gas (plasma) to cut through metal. The plasma is generated by an electrical arc that is created between an electrode and the metal being cut. The plasma is then directed through a nozzle, which is moved by the CNC machine to cut the metal in the desired shape.

Advantages of CNC Plasma Cutters

CNC plasma cutters offer a number of advantages over traditional metal fabrication methods. These include:

- Accuracy: CNC plasma cutters are highly accurate, allowing for precise cuts with minimal waste. This is especially important for complex shapes and intricate designs.

- Speed: CNC plasma cutters are much faster than traditional methods, allowing for faster production times and increased efficiency.

- Cost-effectiveness: CNC plasma cutters are more cost-effective than traditional methods, as they require less labor and materials.

- Versatility: CNC plasma cutters can be used to cut a variety of metals, including steel, aluminum, and stainless steel.

- Safety: CNC plasma cutters are much safer than traditional methods, as they do not produce hazardous fumes or sparks.

Applications of CNC Plasma Cutters

CNC plasma cutters are used in a variety of industries, including automotive, aerospace, and construction. They are used to cut metal components for a variety of applications, such as:

- Automotive: CNC plasma cutters are used to cut metal components for cars, trucks, and other vehicles.

- Aerospace: CNC plasma cutters are used to cut metal components for aircraft, spacecraft, and other aerospace applications.

- Construction: CNC plasma cutters are used to cut metal components for buildings, bridges, and other structures.

- Manufacturing: CNC plasma cutters are used to cut metal components for a variety of manufacturing applications.

Why CNC Plasma Cutters Are the Future of Metal Fabrication

CNC plasma cutters offer a number of advantages over traditional metal fabrication methods, making them the ideal choice for many applications. They are accurate, fast, cost-effective, versatile, and safe, making them the perfect choice for a variety of industries. As technology continues to improve, CNC plasma cutters will become even more advanced, allowing for even greater accuracy and efficiency.

Conclusion

CNC plasma cutters are the future of metal fabrication. They offer a number of advantages over traditional methods, including accuracy, speed, cost-effectiveness, versatility, and safety. As technology continues to improve, CNC plasma cutters will become even more advanced, allowing for even greater accuracy and efficiency.

FAQs

What is a CNC plasma cutter?

A CNC plasma cutter is a computer-controlled machine that uses a high-velocity stream of ionized gas (plasma) to cut through metal. The plasma is generated by an electrical arc that is created between an electrode and the metal being cut. The plasma is then directed through a nozzle, which is moved by the CNC machine to cut the metal in the desired shape.

What are the advantages of CNC plasma cutters?

CNC plasma cutters offer a number of advantages over traditional metal fabrication methods, including accuracy, speed, cost-effectiveness, versatility, and safety.

What industries use CNC plasma cutters?

CNC plasma cutters are used in a variety of industries, including automotive, aerospace, and construction. They are used to cut metal components for a variety of applications.