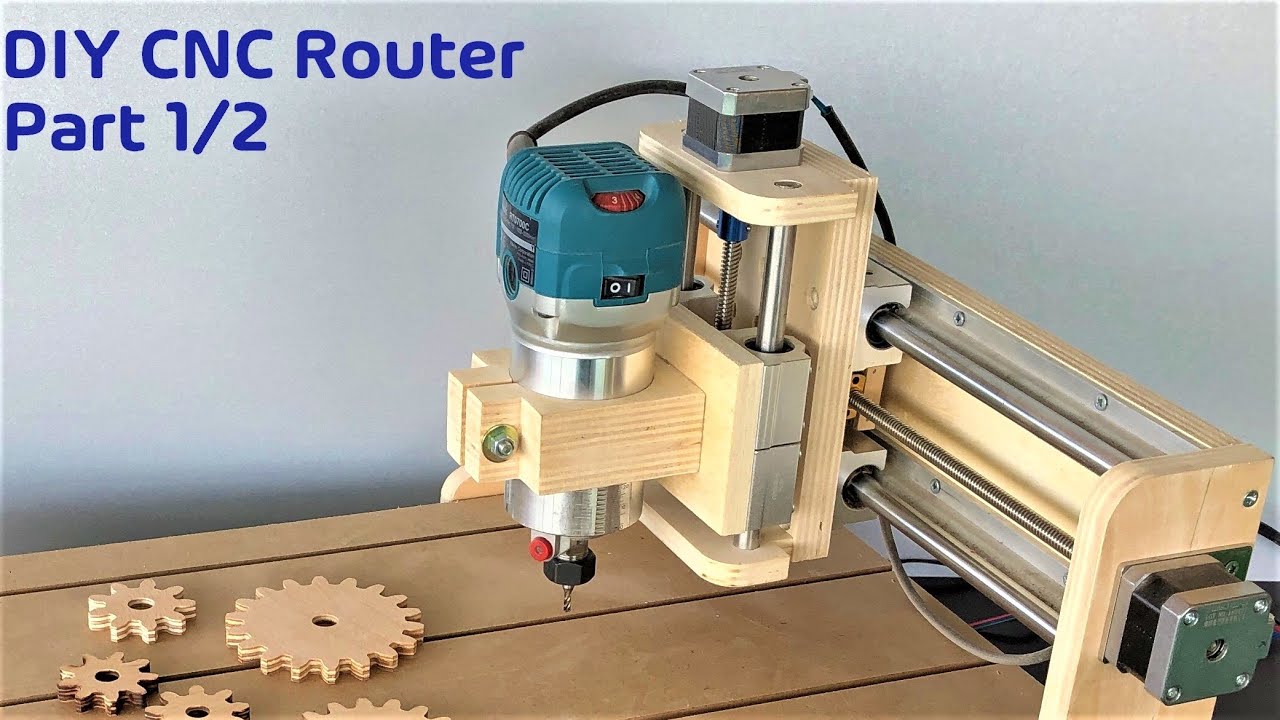

I’ve always wanted to see if I can use a cheap small CNC router to do some custom guitar work. The CNC router I chose for this test is the FoxAlien Master Pro, which has rugged all aluminum construction, a 15.7″‘x15.75″ work area (with extension kit coming soon), accepts a Makita router, and comes in at less than $650. For more information, or to make a purchase, check out the links below:

CNC Router Masuter Pro

https://amzn.to/3Bfz72A

*Prices mentioned in this video are subject to change without notice, please check the links for current pricing.

Full disclosure: I am an Amazon Associate and FoxAlien affiliate, and the links in this description are affiliate links, which means that if you make a purchase, it doesn’t cost you any more money, but I will earn a commission. I would like to thank FoxAlien for sending me this machine for testing and evaluation purposes.

Want a Guns and Guitars shirt? buy one here: https://gunsandguitars.net

Facebook: https://facebook.com/gunsandguitarsofficial

Instagram @gunsandguitarsofficial

Support me on Patreon: https://patreon.com/danthompson

Current Patrons (as of this video)

$5 Patrons:

Yosemite Sam

Mynameisnotjeff

David J Kitelinger

Derek Weathersbee

John Clark

Tanner Redman

David Morgan

David Vaughan

LesLamcke

Fabian Muresan

Alejandro Vega

Captain Rudy 4021

Chris Hopkins

Tony Butterworth

j

Ben Berscak

Jeff Savoie

Mike Bennett

PEEPEE POOPOO

Colin Jenison

Will Fowler

Aidan Peet

Matthew Renegar

Tommy Transplant

Aaron

Daniel Newman

Brian Wigton

Dave Speller

Elijah R Sell

Andrew Epperson

Jeffery A Fallon

Andrew Jeffries

Philip Honeycutt

Travis Blakely

Daniel Russell

Declan Fischer

Paul Messina

Joseph Lacroix

samuel ungeheier

Carlos A. Lizarraga R.

Chriz

Conor O’Doherty

James Populo

Ian Davies

Alex Trocker

Laramie Reg

Troy Thompson

JeffG

Sean Quigg

Dave Van Englehoven

Jamie Cucalon

Maro

Osel Rodrigues

David Anderson

Gerald Ringgold

Brian Brown

Donald West

ChaoticDanny

Ron Clevenger

Matthew Burch

Victor A Estes

Ken Widmer

$10+ Patrons:

Adam West

Brandon Leafblad

Christopher Heath

john best

Nicholas

Peter Champlin

The Grapeman Reform

Marcus Warren

James Lamb

Koss Billingham

Drew Lawton

Jim Shepard

Mark Cockrell

William Herrera

Chris Thomason

John Morris

Patrick Emry

David Capp

Tim Chapin

Timothy Potter

Austin Hewlett

James Robers

Seth Johnson

James Shepard

Touch of Oops

Justin Setters

Jack Stow

Daniel Rota

Michael Fierro

Jeffery Maslan

Johnathan Simmonds

Wolfgang Widmer

James Campbell

Corey Muxlow

Casey Smalley

Tim Stephens

E

Matthew Caffell

Clint Walker

Drew

Al Philp

Robert Lewis

Jaden Bass

Rob Haag

Gregory Clark

JoshuaTroller

Josh Perez

Samuel Ungeheier

Billy Sullivan

Brandonlee

Background music made by Jordan Rowan of iMakeMusic

Audiojungle: https://audiojungle.net/user/imakemusic

source