Why CNC Milling Machines Are Essential for Manufacturing

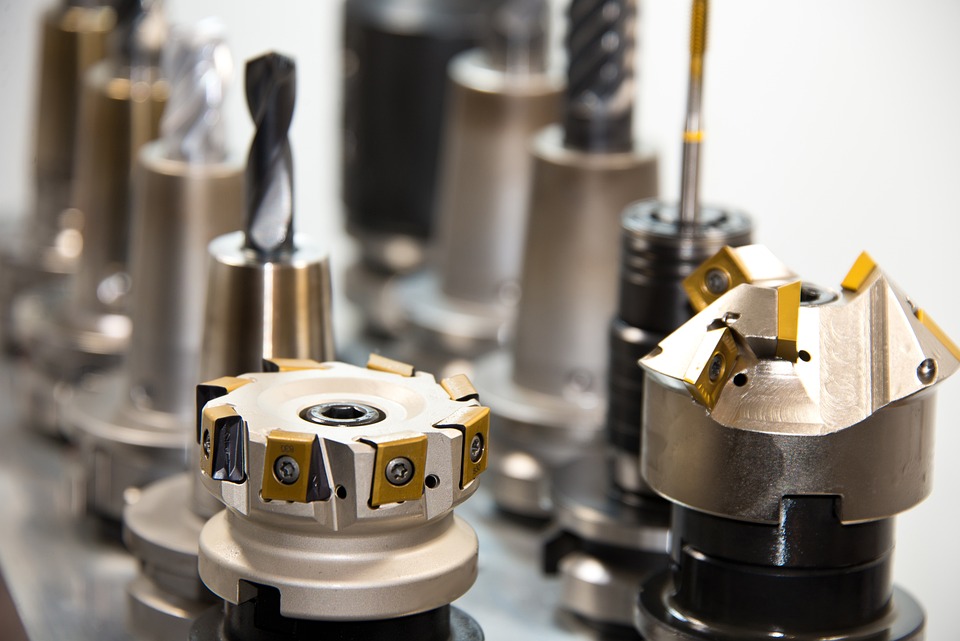

Manufacturing is an essential part of the modern economy, and CNC milling machines are an integral part of the manufacturing process. CNC stands for Computer Numerical Control, and these machines are used to create precision parts and components for a variety of industries. CNC milling machines are used to cut and shape materials such as metals, plastics, and composites. They are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC milling machines are essential for manufacturing because they provide a high level of accuracy and precision. CNC machines are programmed to follow a set of instructions, which allows them to produce parts with a high degree of accuracy and repeatability. This is especially important in industries where precision is critical, such as aerospace and medical. CNC machines are also able to produce complex shapes and contours that would be difficult or impossible to produce with traditional machining methods.

CNC milling machines are also more efficient than traditional machining methods. CNC machines can produce parts faster and with less waste than traditional methods. This is because CNC machines are programmed to follow a set of instructions, which eliminates the need for manual labor. CNC machines are also able to produce parts with a higher degree of accuracy and repeatability, which reduces the amount of time and money spent on rework and scrap.

CNC milling machines are also more cost-effective than traditional machining methods. CNC machines require less setup time and can produce parts faster, which reduces the cost of production. CNC machines also require less maintenance and can be operated with minimal supervision, which reduces labor costs. CNC machines are also more reliable than traditional machining methods, which reduces downtime and increases productivity.

CNC milling machines are also more versatile than traditional machining methods. CNC machines can be used to produce a wide variety of parts and components, including complex shapes and contours. CNC machines can also be used to produce parts with a variety of materials, including metals, plastics, and composites. This versatility makes CNC machines an essential tool for many industries.

CNC milling machines are also more environmentally friendly than traditional machining methods. CNC machines produce less waste and use fewer resources than traditional methods. This reduces the environmental impact of manufacturing and helps to reduce the cost of production.

CNC milling machines are essential for manufacturing because they provide a high level of accuracy and precision, are more efficient and cost-effective than traditional methods, and are more versatile and environmentally friendly. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC machines are an essential tool for many industries and are essential for manufacturing.

FAQs

What is CNC Milling?

CNC stands for Computer Numerical Control, and CNC milling is a machining process that uses computer-controlled cutting tools to shape and cut materials such as metals, plastics, and composites. CNC milling machines are programmed to follow a set of instructions, which allows them to produce parts with a high degree of accuracy and repeatability.

What are the benefits of CNC Milling?

The benefits of CNC milling include increased accuracy and precision, increased efficiency and cost-effectiveness, increased versatility, and reduced environmental impact. CNC milling machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

What industries use CNC Milling?

CNC milling machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC machines are used to produce a wide variety of parts and components, including complex shapes and contours.