The Best CNC Plasma Cutters for Professional Use

CNC plasma cutters are an essential tool for any professional metalworker. They are used to cut metal into precise shapes and sizes, and can be used for a variety of applications. With the right CNC plasma cutter, you can create intricate designs and shapes with ease. In this article, we will discuss the best CNC plasma cutters for professional use.

What is a CNC Plasma Cutter?

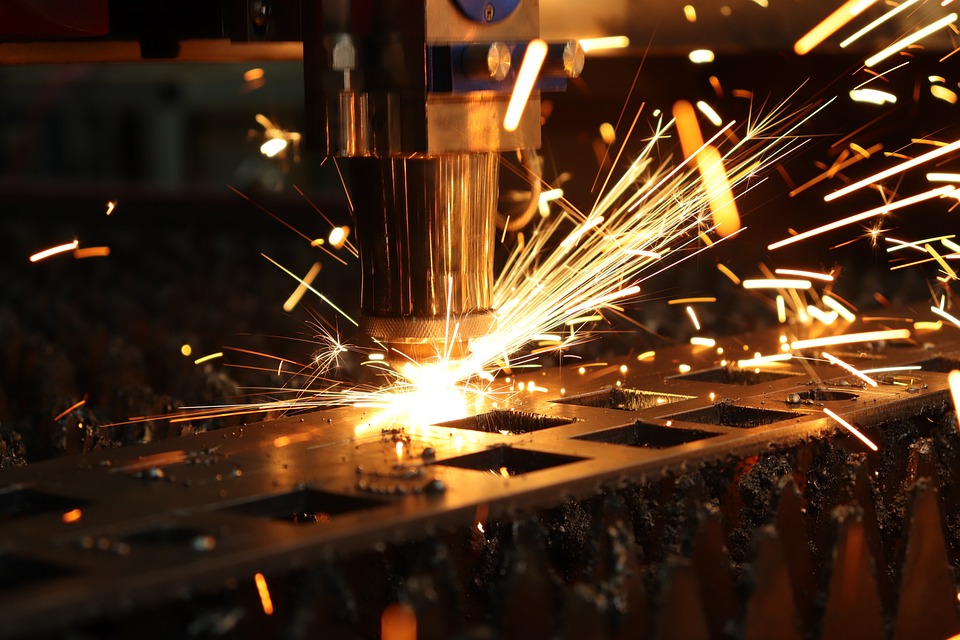

A CNC plasma cutter is a computer-controlled machine that uses a high-velocity stream of ionized gas (plasma) to cut through metal. The plasma is created by an electrical arc that is generated between an electrode and the metal being cut. The plasma is then directed through a nozzle, which is used to guide the plasma stream and create the desired shape.

Types of CNC Plasma Cutters

There are several types of CNC plasma cutters available on the market. The most common types are:

• Handheld CNC Plasma Cutters: These are the most basic type of CNC plasma cutters. They are typically used for small projects and are relatively inexpensive.

• Tabletop CNC Plasma Cutters: These are larger and more powerful than handheld CNC plasma cutters. They are typically used for larger projects and are more expensive.

• Industrial CNC Plasma Cutters: These are the most powerful and expensive type of CNC plasma cutters. They are typically used for large-scale projects and require a significant investment.

Features to Consider When Choosing a CNC Plasma Cutter

When choosing a CNC plasma cutter, there are several features to consider. These include:

• Cutting Speed: The cutting speed of a CNC plasma cutter is an important factor to consider. The faster the cutting speed, the faster the job can be completed.

• Cutting Accuracy: The accuracy of a CNC plasma cutter is also important. The more accurate the cutter, the more precise the cuts will be.

• Power Source: The power source of a CNC plasma cutter is also important. Some CNC plasma cutters are powered by electricity, while others are powered by compressed air.

• Price: The price of a CNC plasma cutter is also an important factor to consider. CNC plasma cutters can range from relatively inexpensive to very expensive, depending on the features and capabilities.

The Best CNC Plasma Cutters for Professional Use

Now that we have discussed the features to consider when choosing a CNC plasma cutter, let’s take a look at some of the best CNC plasma cutters for professional use.

• Hypertherm Powermax45 XP: The Hypertherm Powermax45 XP is a powerful and reliable CNC plasma cutter. It is capable of cutting up to 1/2 inch thick steel and is powered by electricity. It is also relatively affordable, making it a great choice for professional use.

• Miller Spectrum 625 X-Treme: The Miller Spectrum 625 X-Treme is a powerful and reliable CNC plasma cutter. It is capable of cutting up to 1/2 inch thick steel and is powered by electricity. It is also relatively affordable, making it a great choice for professional use.

• Lincoln Electric Power Wave C300: The Lincoln Electric Power Wave C300 is a powerful and reliable CNC plasma cutter. It is capable of cutting up to 1/2 inch thick steel and is powered by electricity. It is also relatively affordable, making it a great choice for professional use.

• ESAB Rebel EMP 215ic: The ESAB Rebel EMP 215ic is a powerful and reliable CNC plasma cutter. It is capable of cutting up to 1/2 inch thick steel and is powered by electricity. It is also relatively affordable, making it a great choice for professional use.

Conclusion

CNC plasma cutters are an essential tool for any professional metalworker. With the right CNC plasma cutter, you can create intricate designs and shapes with ease. In this article, we discussed the best CNC plasma cutters for professional use. We also discussed the features to consider when choosing a CNC plasma cutter.

FAQs

What is a CNC plasma cutter?

A CNC plasma cutter is a computer-controlled machine that uses a high-velocity stream of ionized gas (plasma) to cut through metal. The plasma is created by an electrical arc that is generated between an electrode and the metal being cut. The plasma is then directed through a nozzle, which is used to guide the plasma stream and create the desired shape.

What are the different types of CNC plasma cutters?

The most common types of CNC plasma cutters are handheld, tabletop, and industrial. Handheld CNC plasma cutters are the most basic type and are typically used for small projects. Tabletop CNC plasma cutters are larger and more powerful than handheld CNC plasma cutters and are typically used for larger projects. Industrial CNC plasma cutters are the most powerful and expensive type of CNC plasma cutters and are typically used for large-scale projects.

What features should I consider when choosing a CNC plasma cutter?

When choosing a CNC plasma cutter, you should consider the cutting speed, cutting accuracy, power source, and price. The cutting speed of a CNC plasma cutter is an important factor to consider, as the faster the cutting speed, the faster the job can be completed. The accuracy of a CNC plasma cutter is also important, as the more accurate the cutter, the more precise the cuts will be. The power source of a CNC plasma cutter is also important, as some CNC plasma cutters are powered by electricity, while others are powered by compressed air. Finally, the price of a CNC plasma cutter is also an important factor to consider, as CNC plasma cutters can range from relatively inexpensive to very expensive, depending on the features and capabilities.