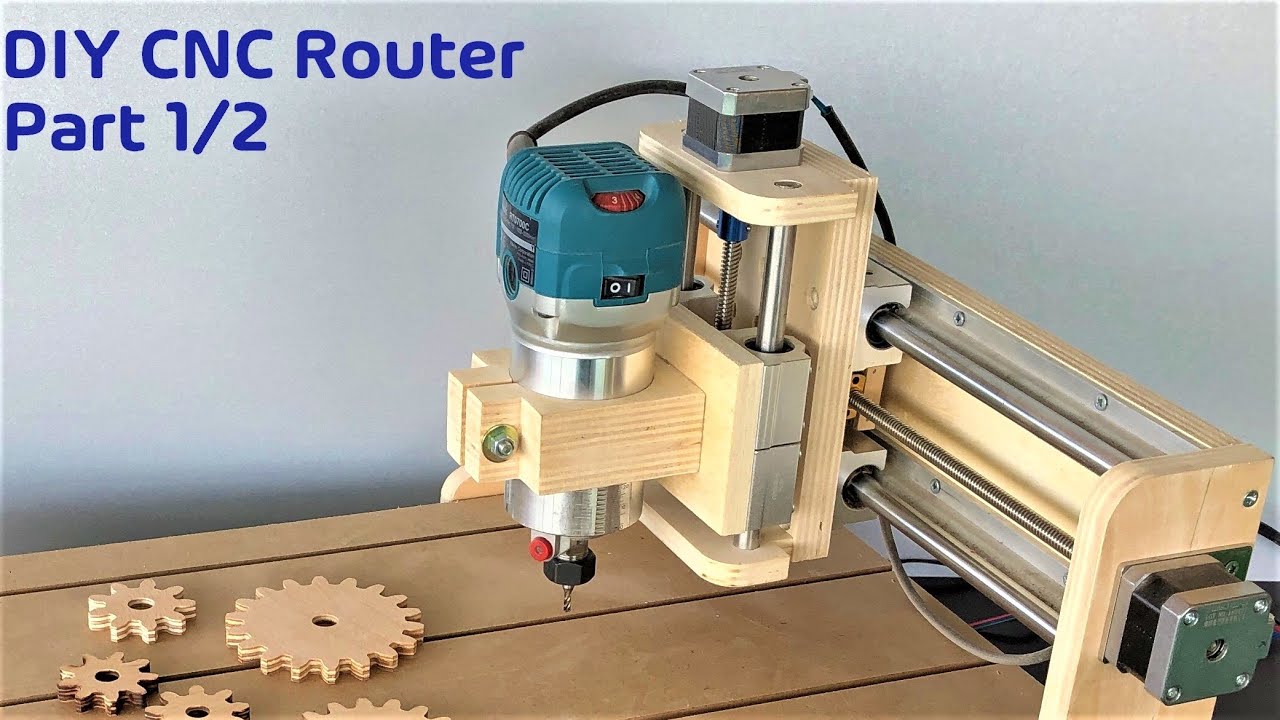

Building OpenSource LowRider CNC Router

Part2 for this video: https://youtu.be/2MP5vhqibmQ

Plan and assembly instructions: https://www.v1engineering.com/lowrider-cnc/

Shopping for parts: https://shop.v1engineering.com/collections/lowrider-parts

Alternative/additional parts used:

Makita router: https://amzn.to/3nYyLVN

Stepper Motors: https://amzn.to/3l31abI

Vacmaster vacuum: https://amzn.to/2J3MwDD

GT2 Timing Belt: https://amzn.to/2V1Nbbk

Lead Screw: https://amzn.to/370UANO

GT2 Timing Pulleys: https://amzn.to/377f3jT

Inline Wheels: https://amzn.to/39hXJeP

GT2 Idler Pulley: https://amzn.to/371LCjk

608-2RS Skateboard Bearings: https://amzn.to/3m3fcuZ

Aluminum Spacers: https://amzn.to/33fCK8R

Braided Sleeving: https://amzn.to/360A6W2

Power Supply: https://amzn.to/3lYVNLP

1/4″ to 1/8″ Collet adapter: https://amzn.to/2JaTBlI

Arduino board: https://amzn.to/362Ycj1

RAMPS 1.4 board: https://amzn.to/2HzkCiz

1/8 End Mills: https://amzn.to/2J7qksf

M4 Steel Nylon Lock Nut: https://amzn.to/2J6ZPTZ

M4 Stainless Steel Round Flat Washer: https://amzn.to/33hSfwK

12864 LCD Graphic Display: https://amzn.to/3m2MZ7O

1/4 Compression End Mill: https://amzn.to/3nTzWWD

60-Degree 1/4 bit: https://amzn.to/379CM39

1/4 Down Cut End Mill: https://amzn.to/3nRXETe

1/8 Straight Flute End Mill: https://amzn.to/2KDtUv4

Mist Coolant Lubrication Spray: https://amzn.to/360WuP6

Bottom Cleaning Router Bit: https://amzn.to/3lap2dy

00:00 Intro

00:16 Router Plate

00:37 Center Assembly

03:32 Slider Assemblies

07:31 Z Assemblies

09:20 Making Sliders fit my table

09:58 Connecting Z & X

14:55 Installing belts

16:26 Wiring

17:02 Firmware install

17:50 Testing

18:37 Final Assembly

22:06 Crown test

23:09 First cuts

source