This time I’m building the Z axis and mounting it to the column. I’m probably going to regret saying this, but hopefully this concludes the majority of the locating, drilling and tapping of holes.

______________________________________

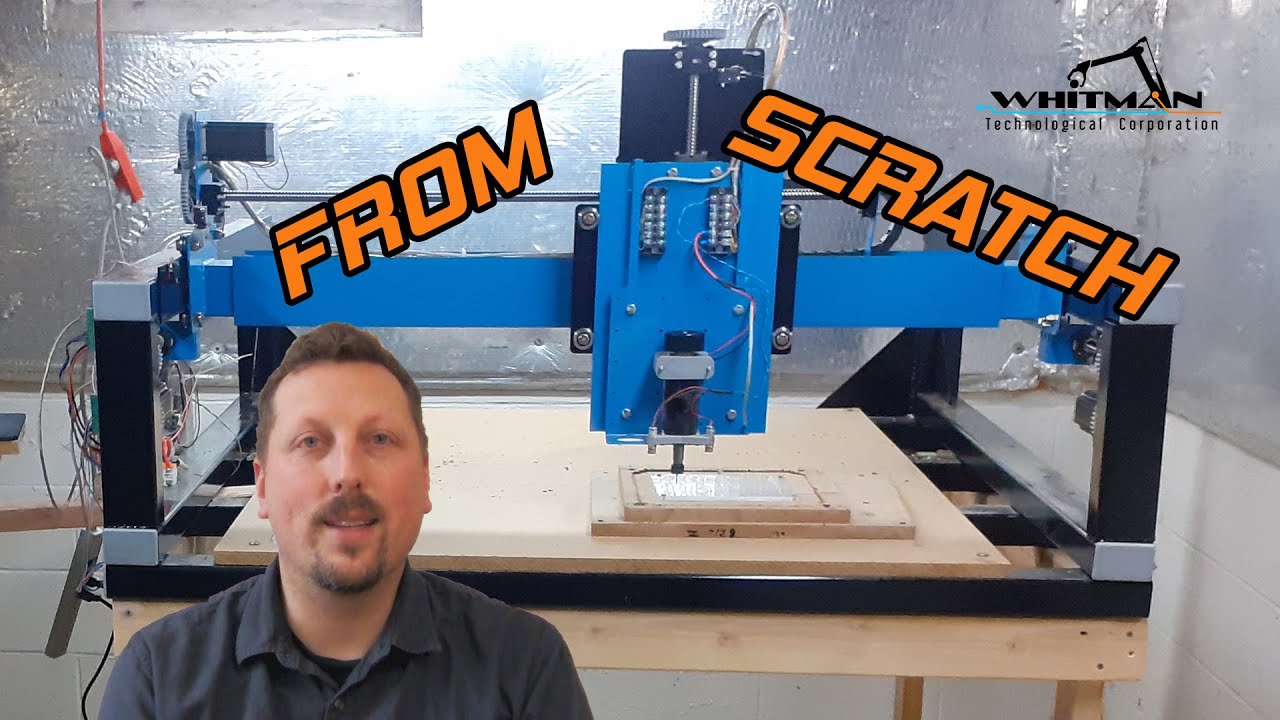

DIY CNC Milling machine build.

My objective for this project is to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to get the axis surfaces flat and parallel.

By using aluminum tool plate (which is in theory pre-machined flat) and bolting the critical components rather than welding, it should be possible to avoid any machine work. After all, I’m building a mill because I don’t have one!

Linear rails and ball screws are the cheap Chinese 20mm style that you can find on eBay etc.

__________________________________

Music Credit

—————–

No Quarter – TechnoAXE

——————

Dark vs. Light – – TechnoAXE

source