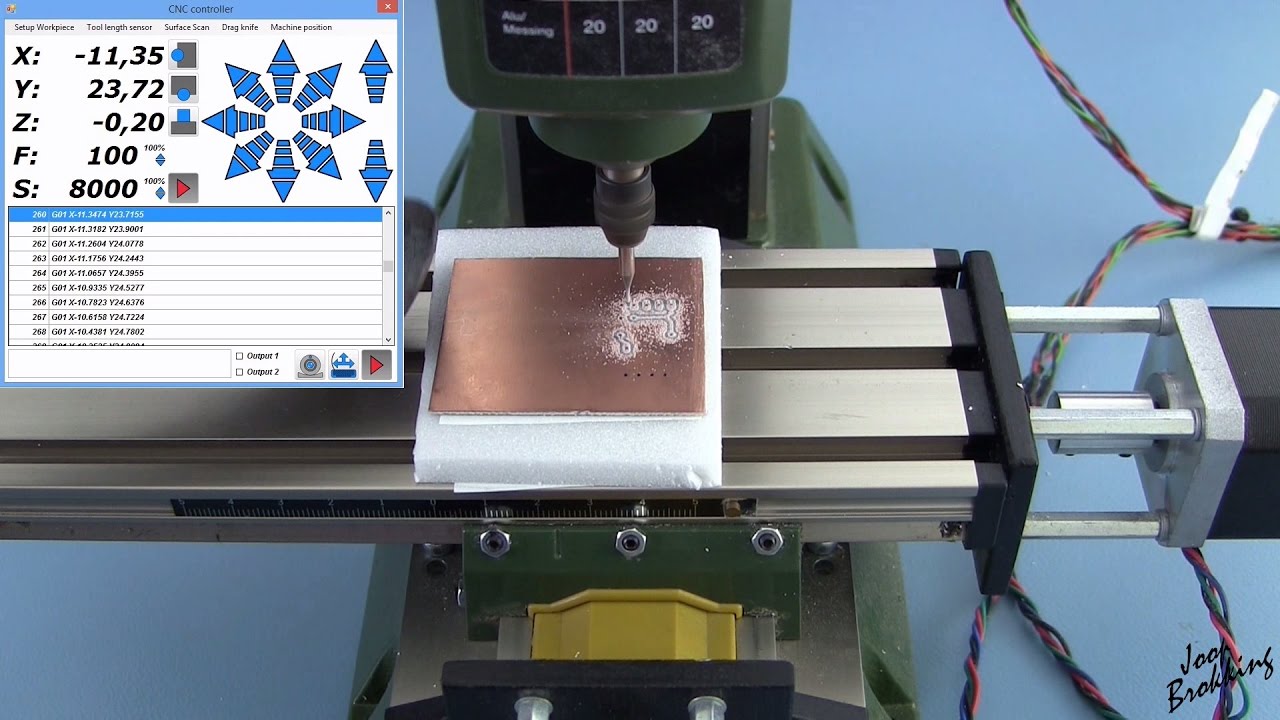

O intuito de fazer uma CNC router caseira é aprender todo o funcionamento e utilização básica destas máquinas, neste video mostro resumido como foi processo meu processo de montagem, peças utilizadas e funcionamento final.

Mais detalhes: http://bit.ly/35LBgSP

Como muitas pessoas me pediram, coloquei os link abaixo:

Cnc shield e drivers: https://amzn.to/2EAMKAa

Kit de fresas: https://amzn.to/3i7k1kq

Kit Arduino: https://amzn.to/3czH9GZ

Apenas Arduino: https://amzn.to/338rHOZ

Motores de passo: https://amzn.to/2Gh0dgV

https://drive.google.com/file/d/0B3HftVqWfJhcM1gwM1JsZ2R1Yjg/view

https://drive.google.com/file/d/0B3HftVqWfJhcaUg5aUtxTGNxYWs/view

https://github.com/grbl/grbl/

https://goo.gl/GeqKQ9

https://drive.google.com/file/d/16iFH-tKXWKOxov-Jl0D3mLe7t99f-Gjj/view

https://drive.google.com/file/d/0B3HftVqWfJhccUR5ZmVCVklONW8/view

Escreva seu comentário, se inscreva também e ative o “sininho” =)

source