Tag: homemade

The CNC has a half sheet of plywood cut capacity with a maximum thickness allowance of 6″. The entire unit cost under $900 to make. A free set of plans and cost breakdown analysis (with links to every product used) is available for download on my website DIYBuilds.ca

Support DIY Builds on Patreon:

https://www.patreon.com/DIYBuilds

Buy a T-shirt to support the channel:

https://teespring.com/stores/diy-builds

Visit my website for free plans and see viewer builds:

http://diybuilds.ca

Follow me on Instagram:

https://www.instagram.com/diybuilds

Follow me on Facebook:

https://www.facebook.com/DIYBuilds

#DIY

#Woodworking

#CNC

source

The CNC has a half sheet of plywood cut capacity with a maximum thickness allowance of 6″. The entire unit cost under $900 to make. A free set of plans and cost breakdown analysis (with links to every product used) is available for download on my website DIYBuilds.ca Support DIY Builds on Patreon: https://www.patreon.com/DIYBuilds Buy a T-shirt to support the

Building a CNC plasma table from scratch finally after many-many months has come to an end. After some steel work, fabrication and welding and months of head scratching and trial & error in the software and hardware department I’m glad to say it’s finally finished. This video shows you the very first and awful test cuts with horrible results we encountered in the beginning. But cut after cut the machine got tweaked, each following cut got better and better and finally it works as it should. I learned a lot in the process in the making of this table and have to thank my buddy for designing and building it. Cheers, Blackloop CNC!

I hope you enjoy the video! New 4×4 Off-Road UTV video next week and thanks for watching!

Check out my other videos on my channel page: https://www.youtube.com/c/DonnDIY

#donndiy #homemade #cnc

Soundtrack:

Pomade – Silent Partner (YouTube Audio Library)

Welding equipment borrowed from Spetselektroodi AS, Estonia:

Fronius TransSteel 2700 welder

Optrel Crystal 2.0 Welding Helmet

Hypertherm Powermax 45 XP plasma cutter

source

Building a CNC plasma table from scratch finally after many-many months has come to an end. After some steel work, fabrication and welding and months of head scratching and trial & error in the software and hardware department I’m glad to say it’s finally finished. This video shows you the very first and awful test cuts with horrible results we

Instructions for a 1 to 2 day build on a CNC Plasma Cutter

Plans – https://jdsgarage.bigcartel.com/

For all inquires email us jsaction4[at]gmail.com

#CNC #Plasmacutter #DIY

source

Instructions for a 1 to 2 day build on a CNC Plasma Cutter Plans – https://jdsgarage.bigcartel.com/ For all inquires email us jsaction4[at]gmail.com #CNC #Plasmacutter #DIY source

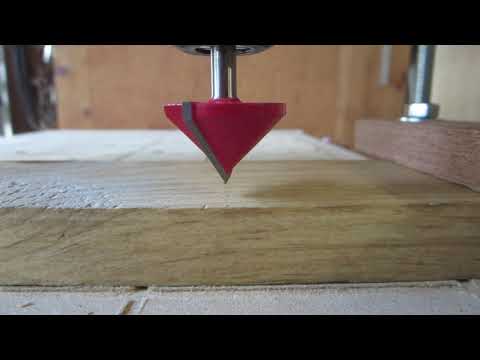

DIY CNC Milling machine build.

My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to get the axis surfaces flat and parallel.

By using aluminium tool plate (which is in theory pre-machined flat) and bolting the critical components rather than welding, it should be possible to avoid any machine work. After all, I’m building a mill because I don’t have one!

Linear rails and ball screws are the cheap Chinese 20mm style that you can find on eBay etc.

source

DIY CNC Milling machine build. My objective for this project was to design and build a CNC milling machine without the need for any machining of the parts. Ordinarily, building a mill requires a much bigger mill to get the axis surfaces flat and parallel. By using aluminium tool plate (which is in theory pre-machined flat) and bolting the critical