In this episode, Jim Colt, an industry veteran from Hypertherm, talks about the daily maintenance of a CNC plasma cutting table. Visit https://www.maverickcnc.com/ for more information on all of our plasma cutting table

What is the daily maintenance of a plasma cutting table? MaverickCNC and Hypertherm have some basic guidelines for keeping your equipment running in excellent condition.

Be sure to subscribe to our channel and click the bell icon to get notified when new “Tips and Tricks from Jim Colt” videos are released.

Video description :

Hi, this is Jim and I’m here with MaverickCNC. Let’s talk about a few little maintenance things that probably ought to be done on every CNC machine on a daily basis and especially, some of them have, some machine have different effects depending on whether you have a downdraft table or a water table.

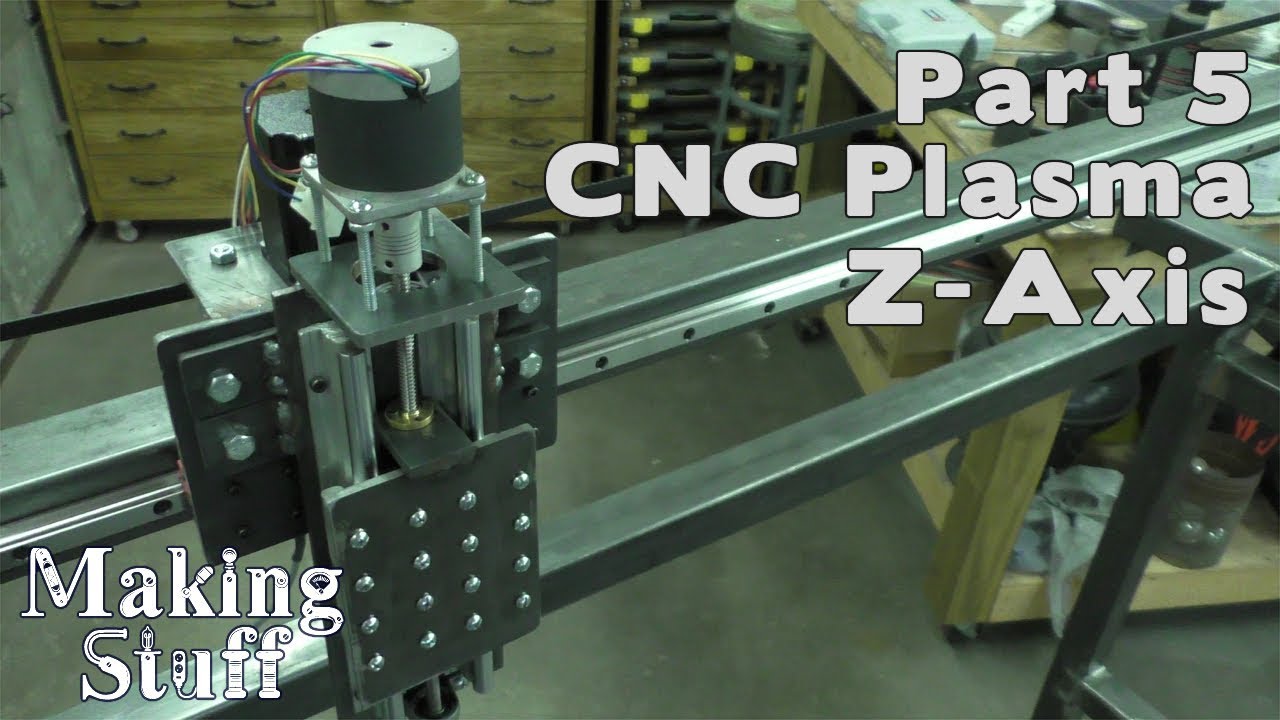

This particular one is a water table and during the cutting process there’s always a little bit of splash of water. Water does a great job of controlling the fumes but it does tend to splash up on the table a little bit and consequently with a downdraft table******* also if it’s properly designed does a great job controlling the fumes, doesn’t splash up but there will be a little bit, maybe a little residual smoke and so forth and one of the things you want to watch for, on this MaverickCNC machine is these V rails, these are the guide rails that go around.

It’s a very good way for a machine to be built that’s going to operate in a dirty shop because there’s a V that goes this way and there’s a roller wheel that rides on the V and the dirt that lands on there, generally falls off over a period of time, doesn’t build up very much so it’s a good way to design a machine and for a good long lasting machine in the shop. But you still, if you get water splash up on this part of the machine, it’s a good idea to wipe it off.

Take a look at the rack and pinon gear. This is the rack gear, the pinon gear is down inside. Maybe blow it off with an air hose. It’s probably not the best idea to use a lot of lubricant on it. I usually suggest a dry lubricant, like a graphite type lubricant on these because the dust will stick to a wet lubricant, it’s not going to stick so easily to a dry lubricant so keep these clean. There are also some on the side of the machine over there. Another good thing, every once in a while, just check, put your hand on the torch carriage first thing in the morning and kind of push it back and forth in the X direction and push it a little, back and forth, in the Y direction. What your looking for is backlash, if you feel any slop in the motion, then you have to take a look.

You can have something like a worn pinon gear, you can have something that’s out of adjustment, a loose set screw or something like that. Something you may want to talk to tech service about if you feel that backlash. That backlash will affect cut quality, it will affect the roundness of holes, it will affect how, especially if your cutting parts with diagonal cuts in them, it will show as a really rough cut on a diagonal so backlash is a bad thing. This is a nice tight machine. I don’t think we’re going to have any problems with this one.

source