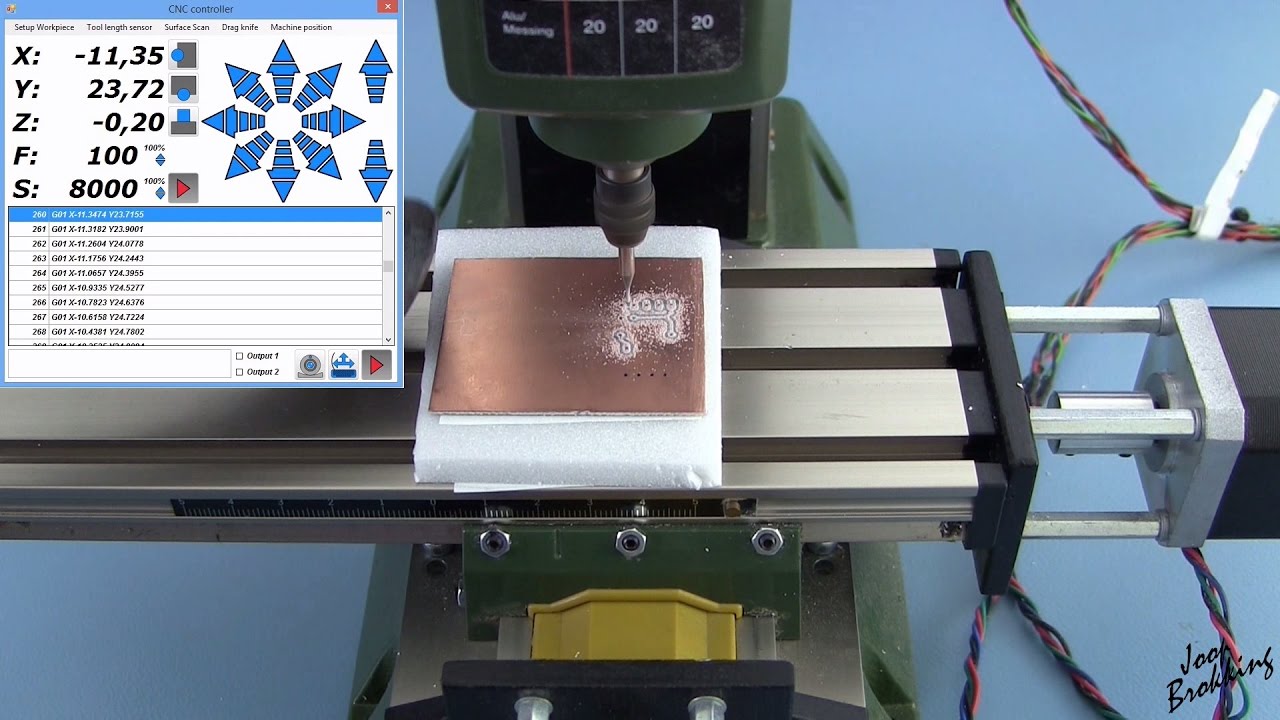

In this video I’m going mill a printed circuit board. Something that I wanted to try for quite some time now. It’s milling a PCB. And yes, it’s Windows only.

Parts for making your own CNC machine.

Stepper drivers:

http://www.dx.com/p/geeetech-stepstick-drv8825-stepper-motor-driver-carrier-reprap-4-layer-pcb-heat-sink-purple-366006?Utm_rid=78761898&Utm_source=affiliate

Stepper motors:

http://www.dx.com/p/geeetech-1-8-degree-nema-14-35-byghw-stepper-motor-for-3d-printer-black-386069?Utm_rid=78761898&Utm_source=affiliate

Arduino Uno:

http://www.dx.com/p/uno-r3-development-board-microcontroller-mega328p-atmega16u2-compat-for-arduino-blue-black-215600?Utm_rid=78761898&Utm_source=affiliate

How to connect the drivers to the motors and Arduino:

https://www.pololu.com/product/2133

PCB-GCODE:

http://pcbgcode.org/

Estlcam:

http://www.estlcam.com/

Eagle PCB design:

https://cadsoft.io/

LibreCAD for creating Autocad drawings

http://librecad.org

source