MORN LASER has 18 years manufacturing experience of CO2 laser machine, fiber laser machine. Customizable service is available. MORN LASER, MAGIC LASER.Email:[email protected] / whatsapp: +86-18660129581

1 Brief description of the fiber laser technology

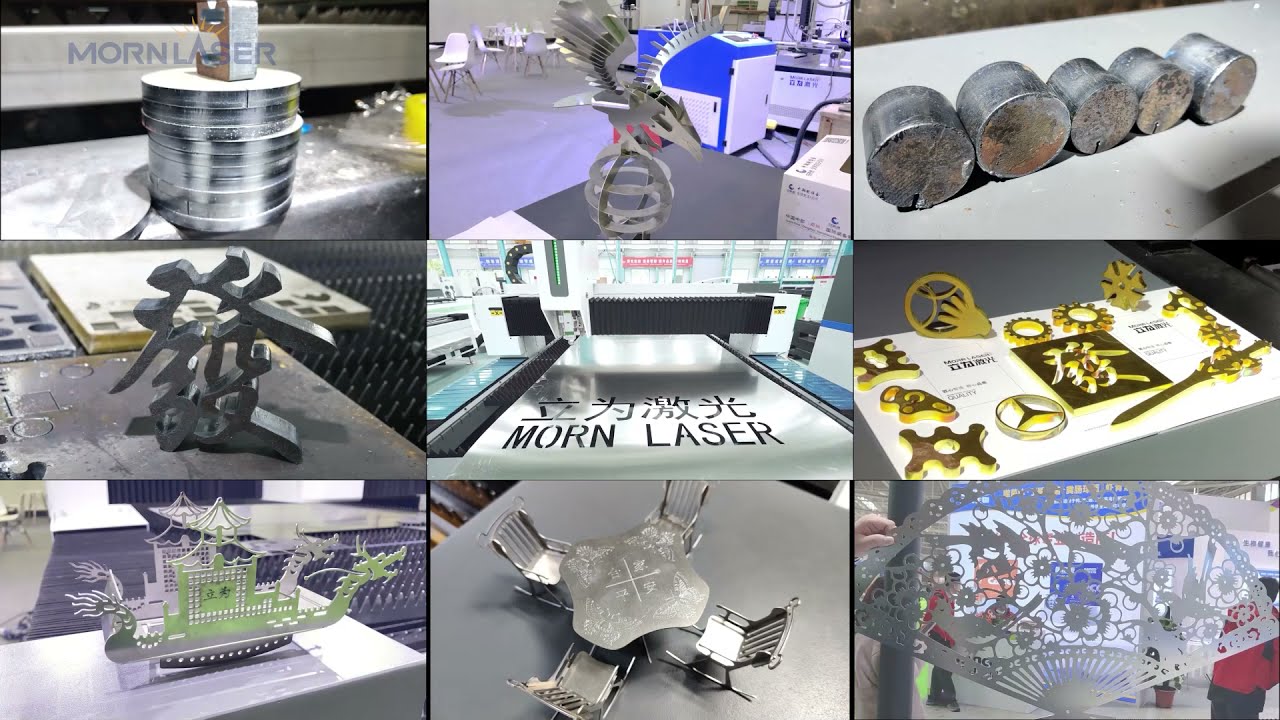

Fiber laser technology has become a new star in laser industry and an emerging leader in sheet metal cutting field.

Fiber laser technology works in the way that a fiber laser beam is focused highly on the surface of materials being cut, in which the laser beam of high energy density transforms into great heat with intensified temperature. Being exposed to such heated and focused laser beam, the surface of materials will melt or vaporize instantly, and meanwhile the gas will be blown into the surface of material to sweep off the residue of powder caused from melting materials.

2.What should you know about MORN LASER fiber laser cutting machine?

1). Fiber laser cutting machine is for metal precise cutting powered by fiber laser technology. MORN LASER quality fiber laser beam results in faster cutting speeds and higher quality cuts compared to other cutting solutions. The key advantage of a fiber laser machine is its short beam wavelength (1,064nm). High peak power and nanosecond pulses

contribute to an efficient work in fiber laser engraving and marking.The wavelength, which is ten times lower than that of C02 laser, generates high absorption into metals. This makes the fiber laser machine become a perfect tool for cutting metal sheets of stainless steel, carbon steel, mild steel, aluminum, brass, etc.

2). Compared to traditional CO2 laser machines or YAG lasers, the fiber laser has higher efficiency and are more versatile in metals processing, especially for sheet metal engraving, cutting and marking. Also, when cutting a wide range of metals, the fiber laser machines all can cut in a very precise way accompanied with high quality cutting edge and faster speed.

3).Fiber laser adopt the reliable emitting diodes with projected lifetimes more than 100,000 hours of continuous or plaused operation.

4). MORN LASER software allows the users full control of the fiber laser capabilities, such as control power, modulation rate, pulse width and pulse shape.

5). MORN fiber laser cutting machine equipped with fiber laser 500W, 1000W, 2000W, 3000W (optional). Low operating and maintenance costs. Achieve long-term return on investment and revenue maximization.

6). Enclosure design conforms to CE standard for reliable and safe processing. Pallet changer is convenient for material uploading and unloading and further improving working efficiency.

7). Aiming at high speed cutting, strengthened welded machine body after 2 times of aging process, ensuring long-term accuracy and stability of performance.

3 Applications of the fiber laser cutting machines.

Advantages of fiber laser help this technology to be welcomed by various industries. And application of fiber laser are mainly constituted by fiber laser engraving, cutting and marking with high precision, lower cost and faster speed.

1). High precision sheet metal processing

2). Advertising signage

3). Automobile manufacturing

4). Mechanical equipment production

5). Electrical equipment production

4. MORN LASER products service

1). Before sale: We will try to know your requests about what work you will do and help you

choose the most suitable machine specification & give you the best solution.

2). During production: We will send photos of machines during production. so customers

can know more details about the procession of making their machines.

3). Before shipping: We will confirm the specification of order to avoid the mistake and we

will test & adjust the machine until it has the best performance.

4). After shipping: We will give you the tracking information of the sea vessel so customers can know when it will arrive at your port and make enough preparation.

5). After arrival:We will confirm with you if machine is in good condition. and see if any spare parts were broken during sea shipping then help to solve the insurance.

5. Contact with us

The low-cost operation and perfect cutting results of MORN fiber laser machines have attracted more effort of people from all over the world to be thrown into long term cooperation with MORN LASER .

And for more details, please contact us directly.

Email:[email protected]

Mobile Phone/whatsapp/Viber/Wechat:+86-18660129581

Catalog: People & Blogs

License: Standard Youtube License

source