#FabricationTips #KevinCaronArt

From http://www.kevincaron.com – Artist Kevin Caron explains why he chose to buy the Dynatorch Super B CNC Plasma Table, from features to support ….

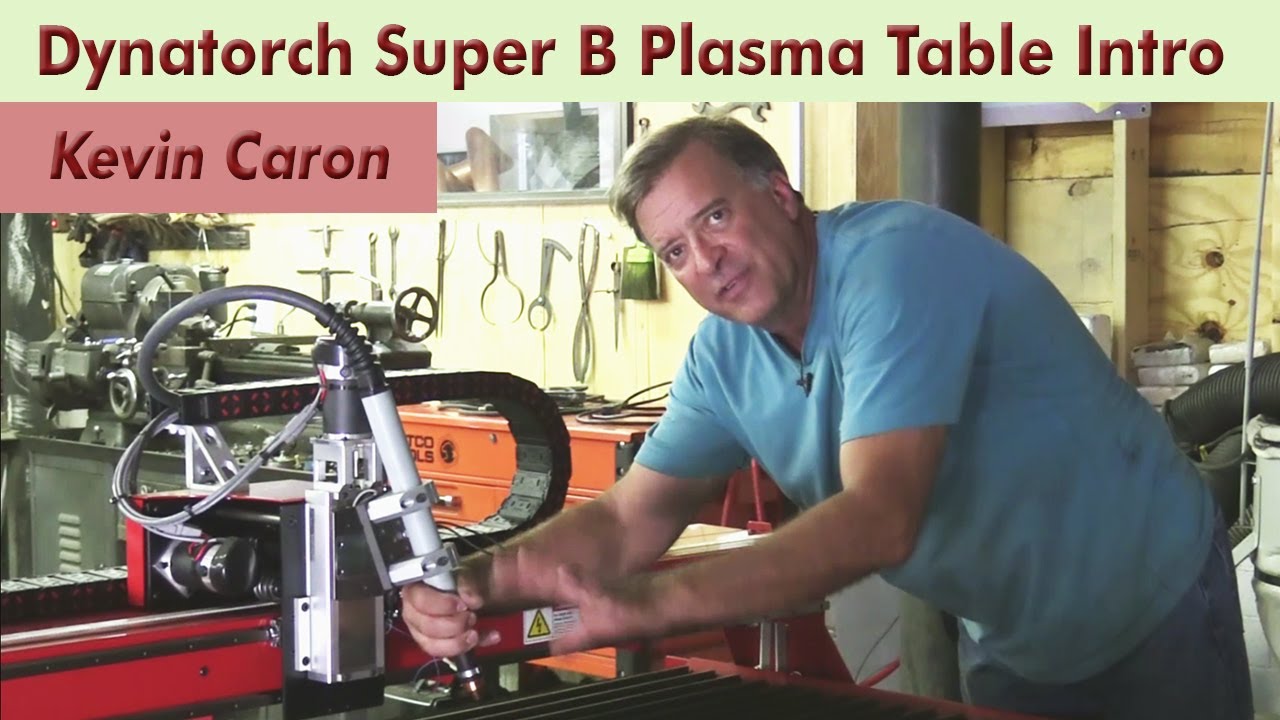

Kevin Caron just bought a new Dynatorch Super B 4×4 Plasma CNC table.

A plasma CNC table is a plasma cutter – like a handheld plasma torch used to cut metal, but the torch is attached to a gantry that moves it back and forth. It’s computer controlled – you design the part in CAD, then run your file through another format that the machine can see. Then you bring the file to the table and let it do all the cutting for you. Kevin Caron is going to do a series on the table, explaining how to use the software so everything can talk together, showing how the table cuts, etc.

The best thing about a plasma CNC table? It gets rid of the shake from a handheld plasma torch. When Kevin Caron is using a handheld torch, you can literally see the result of his heartbeat in the shake of the cut.

If you’re not running your handheld torch against a guide, you’re going to have a wiggle. Now this table will be Kevin Caron’s new guide.

Of all the plasma cutting CNC tables available, the reason Kevin Caron bought a Dynatorch is that it seems to be the best made. It has the thickest metal – he checked the shipping weight of available tables to see which was the heaviest for its size.

This table also came with the plasma cutter. You can pick which size of plasma cutter you want – what amperage you want based upon how thick of metal you want to cut – but the table includes the plasma cutter itself. It also came with the right torch for that size of plasma cutter.

It included a desktop computer with the software already loaded.

There were also cut marks in the table where they had tested it before shipping it to Kevin Caron. Dynatorch had hooked up that desktop computer and that plasma torch and cut on that table – they even sent a disk showing it in operation so you know it was running before they put it in the crate.

The biggest thing that persuaded Kevin Caron to choose Dynatorch, though, was the tech support. The company put an extra program on the computer that allows a customer call tech support, push one button (or two) on the computer, and let Dynatorch run the table remotely.

Kevin Caron can talk with them at the same time, while they run the computer, then use the camera and speakerphone on his phone to show them what is happening. “It’s just like having the guy standing right there next to you,” says Kevin Caron.

Some other cool features: the torch is mounted on magnets. So if anything should hit it, it releases and the machine turns off.

Kevin Caron got the optional stainless steel water pan that sits underneath the cutting area. You fill it up about halfway with water, then, as you are cutting, the water helps contain the dust and smoke.

Kevin Caron really likes that the company thought about all of these details.

He’s played with the CNC table a little so far, making some parts for his sculpture Roundabout ( http://www.kevincaron.com/art_detail/roundabout.html ). As soon as he gets more experienced with the table and process, he’ll show how to start, then make a part right through cutting, walking everyone through the whole process.

Kevin Caron is ready to make some more parts, so you have time to subscribe to this channel to see new how-to videos every Wednesday, and to visit http://www.kevincaron.com to see his wild work.

Well, you might want to stick around another moment to see Kevin Caron display his graceful side ….

“Inspired sculpture for public & private places.”

Artist Kevin Caron has been sculpting full time since 2006. See – and hear – his amazing metal and large format 3D-printed sculptures, which are found in public and private places coast-to-coast and online at http://www.kevincaron.com.

Follow me for more fun and facts:

Facebook:

https://www.facebook.com/kevincaronstudios

Instagram: http://www.instagram.com/kevincaronart

Twitter: https://twitter.com/kevincaronart

source