https://sunspire.site/

https://www.sunspire.ru

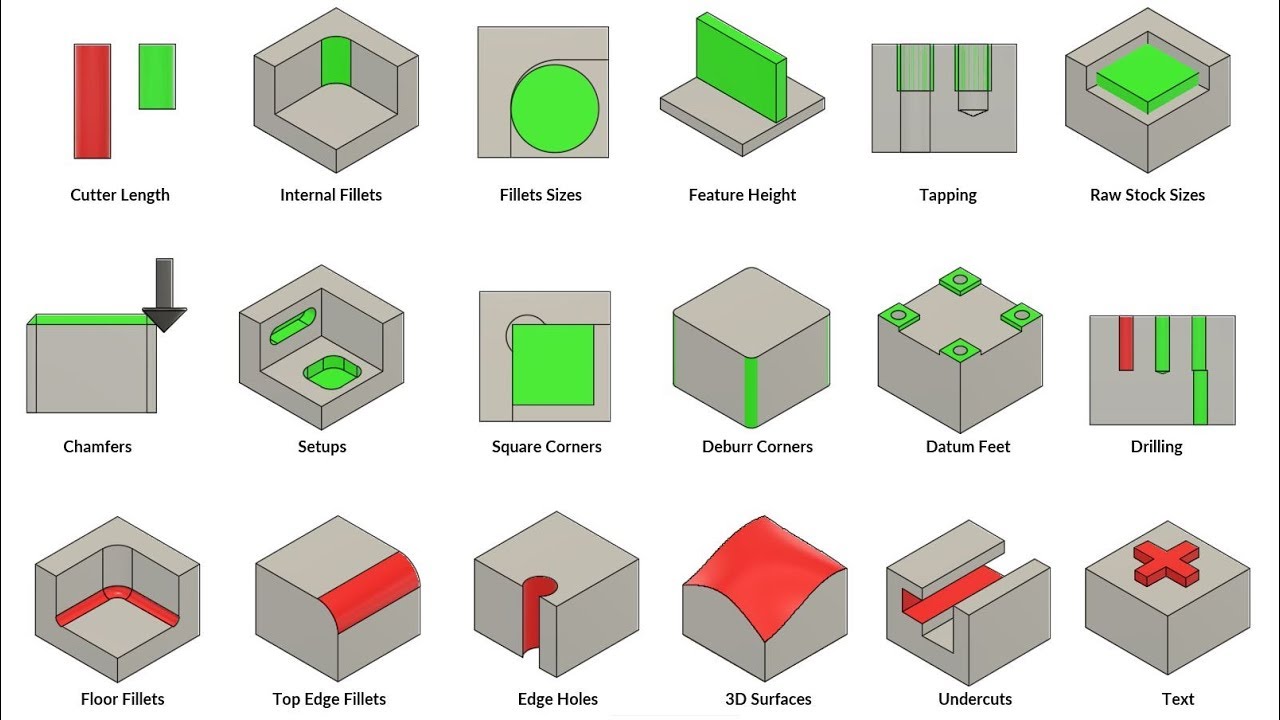

CNC milling machine simulator is a multimedia application designed to provide a basic introduction to beginner mechanical engineering professionals with the principles of programming operations for milling parts using a standard (ISO) G-code.

The main task of the application is syntactic analysis of the code of control programs in order to build a graphical model of cutting tool trajectories in three-dimensional space.

The main functions: editing the code of the control programs of the milling machine, operations with files of control programs, setting the geometric parameters of the cutting tool, continuous/step-by-step execution of blocks of control programs, three-dimensional visualization of tool movements in the working space of the machine, simplified visualization of the machined surface of the part, calculation of processing modes, a quick reference guide to using G-code.

#cncsimulator #milling #machine

source