*footage is slightly sped up because it looks so cool*

Video Credit: Guhring

If you need parts CNC machined, look no further! Get high-quality parts delivered as fast as next-day.

Join over 3,000 companies that have made the move to Fictiv to meet challenging timelines & geometries for custom parts. Get your instant quote today!

https://www.fictiv.com

If you are a machine shop looking for more work, we can help! Apply below to become a Fictiv Manufacturing Partner…

https://www.fictiv.com/become-a-partner

What is CNC Machining?

CNC stands for computer numerical control. So, CNC machining is any kind of machining process controlled by a computer. Computerized automation allows parts to be made more quickly, accurately, precisely, and with more complex geometries than those produced via manual machining. CNC also reduces manual machining labor that would otherwise be done by humans. While they aren’t machining each part themselves, people are essential for programming and operating the machines, ensuring that every operation goes smoothly.

About the CNC Machining Process

CNC, or computer numerical control machining, is a subtractive manufacturing method that leverages a combination of computerized controls and machine tools to remove layers from a solid block of material. The desired cuts in the metal are programmed according to corresponding tools and machinery, which perform the machining task in an automated fashion.

Types of CNC Machining

Depending on the type of part that needs to be machined, there are different types of CNC machines best fit for the job. CNC milling utilizes CNC mills, which consist of a multi-axis system (three, four, or five axes, depending on the part complexity). CNC turning involves Lathe machines, which generally have two axes and cut pieces using a circular motion. Electric discharge machines (EDM) utilize electrical sparks into order to mold work pieces into the desired shape. Hobbing is another type of machining process used for cutting gears, splines, and sprockets. Additional CNC machine types include plasma cutters and water jet cutters.

How Does CNC Machining Work?

The programs used for CNC machining these days are written with G-code, and are usually automatically created by CAM software. CAM, or computer aided manufacturing software, generates the G-code for a 3D model with given tools and workpiece material. This G-code controls the CNC machines, i.e., the motion of the tool, the workpiece, and any tool changes. It even has commands to turn on or off the coolant and other auxiliary components.

CNC machining can be used for a wide variety of materials, with the most common being aluminum, steel, brass, ABS, Delrin, and nylon. But really, almost any hard material can be CNC machined. We’ll discuss the materials more in-depth later on.

CNC vs 3D Printing

Compared with parts manufacturing through additive methods, CNC machined parts are functionally stronger and typically have superior production quality and finish. Thus, CNC machining is typically used in the mid to late stages of development when parts are ready to be tested for functional accuracy.

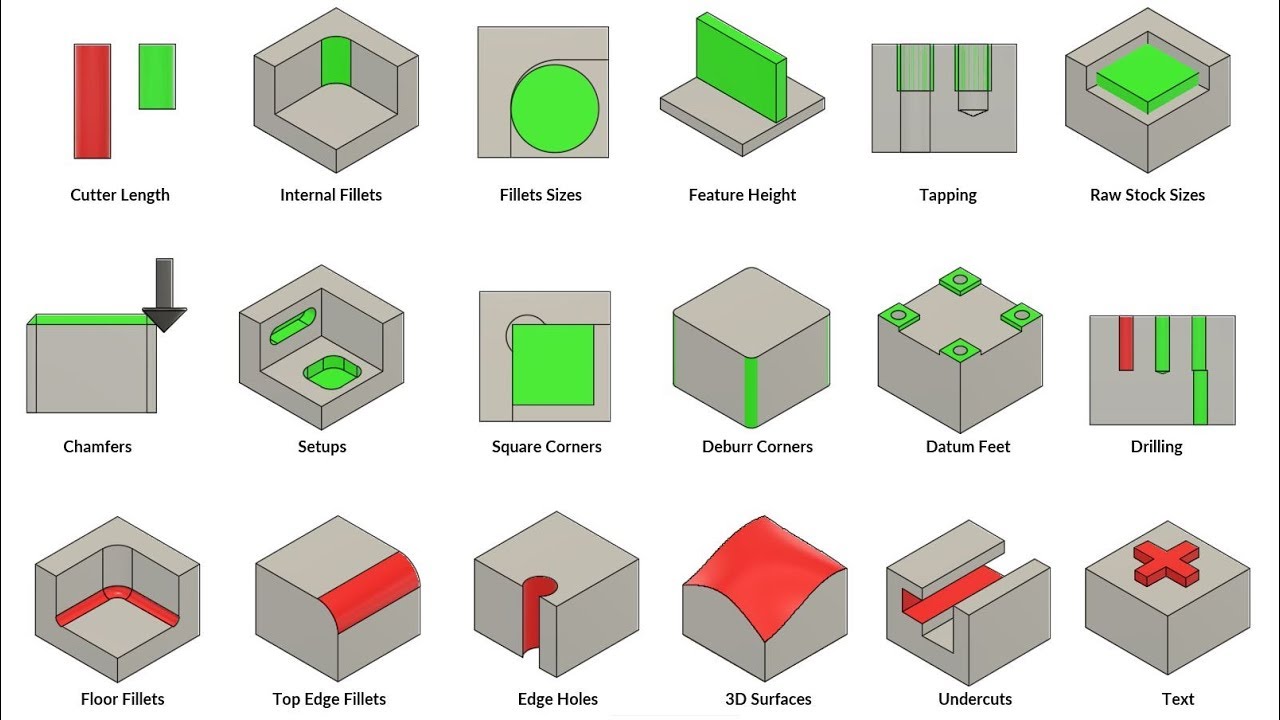

CNC Design Considerations

While most of the details, such as tooling, spindle speed, cutter type, and depth of cut, and taken care of at the machine shop, there are some key things you can do while designing your parts to not only make sure they can be made but also ensure you develop a lean product that doesn’t break the bank.

The primary advantages of CNC machining include rapid prototyping and the ability to produce full-scale production parts quickly. It offers a high level of precision and accuracy in manufacturing parts and allows for tight tolerance machining for CNC parts of all sizes. It also offers maximum flexibility across volume, pricing, lead times, and the range of materials and finishes being used.

The two primary CNC machining processes are CNC turning and CNC milling. Other machining processes include drilling, gear hobbing and electrical discharge machining, among others.

Industries that use CNC machining include aerospace, automotive parts manufacturing, medical machine manufacturing, transportation, defense, and marine industries, along with oil and gas industries and electronics. CNC machining has allowed these industries to become more efficient at mass-producing custom CNC parts.

The standard machining tolerance is ± 0.005″ or 0.13mm. Tolerances are the allowable range for a dimension. If a CNC machining tool has a tolerance of ± 0.01 mm this means that the machining tool can have a deviation of 0.01 mm in every cut. With a drawing, Fictiv’s CNC machining service can produce CNC parts with tolerance as low as ± 0.0002 in. Without a drawing, all CNC parts are produced to our ISO 2768 medium standard. We can also machine to tighter tolerances, ±0.025mm or ±0.001″, with an attached engineering drawing calling out critical features.

#cnc #cncmachine #machining

source